oil-free compressor

AIRBOX® Z

IE4 engine Super Premium Efficiency

IE3 engine Premium Efficiency

IE2 engine High Efficiency

IE1 engine Standard Efficiency

Oil-free compressor

exceptional air quality

In industries where pollution is not an option, Airbox's water-lubricated oil-free compressors ensure 100% oil-free air, low energy consumption and quiet, reliable operation.

Designed for 24/7 operation, these units represent the best in technology, sustainability and continuous performance.

The oil-free compressor is designed to deliver clean, quiet and efficient performance. Its oil-free technology provides key advantages that make a difference in demanding environments and a wide variety of applications.

Key Benefits why choose the oil-free compressor.

Oil-free air

The compressor is capable of delivering 100% contaminant-free air, ideal for sensitive industries such as food, pharmaceutical and electronics.

Energy saving

Significantly reduces power consumption thanks to an optimized design that maximizes efficiency and minimizes energy losses.

Low noise level

It features quiet operation that allows installation close to the point of use, improving the working environment.

Compact design

This series is characterized by small footprint, facilitating installation even in areas with size or access restrictions.

Lower operating cost

The system allows less maintenance, without oil changes or contaminant filters, reducing the total cost of ownership.

AIRBOX® oil-free compressors are the ultimate solution for industries that demand efficiency, purity and sustainability.

free quote

Oil-free compressor applications

Designed to meet the highest standards of purity, oil-free compressors guarantee 100% oil-free air, ideal for processes where contamination is not an option. Thanks to their quiet operation, low energy consumption and compact design, they are easily integrated into environments with critical requirements.

Food and beverage industry

Perfect for bottling, packaging and pneumatic handling processes, it features an integrated dryer that maintains air purity and simplifies logistics by eliminating complex installations.

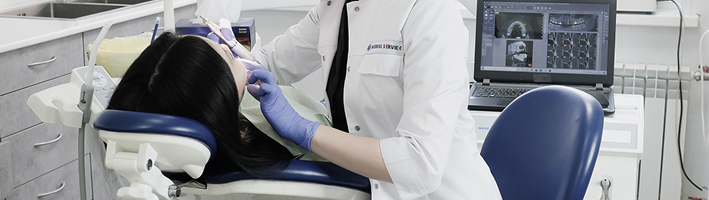

Biomedical and healthcare sector

Ideal for dental offices, outpatient clinics and small laboratories, with low noise level and tight dimensions, facilitating its location in sensitive areas without interrupting medical activities.

Electronics and specialized manufacturing

Ideal for prototyping workshops, assembly of smaller scale components and testing of electronic boards, with easy maintenance and less vibration, compatible with spaces that require mobility of the equipment.

Technical textiles

Optimizes spinning and finishing processes with clean, constant air; avoids residues that can affect fabric quality.

Aerospace and defense

System capable of supplying pure air for high-precision control, testing and assembly systems, without compromising delicate components.

Pulverization, solar energy and water treatment

Supports critical manufacturing and panel cleaning processes, ensuring clean, dry air for maximum efficiency and durability.

AIRBOX® oil-free compressors are the ultimate solution for industries that demand efficiency, purity and sustainability.

free quote

the smarter way to manage your air compressors

PRO

Real-Time Remote Monitoring

Total control

Monitor pressure, temperature, operating hours and any other key compressor parameters from your computer, tablet or smartphone.

Smart alerts

The app sends real-time notifications when it detects abnormal variations, helping you act before major problems arise.

FREE

Maintenance and Digitalized Spare Parts

Automatic scheduling

The application keeps a maintenance log, scheduling upcoming maintenance and service reminders based on working hours or usage conditions.

Spare parts request

When it's time to replace a component, Airvice suggests the necessary parts and can connect directly with the service technician or your trusted supplier.

FOR DISTRIBUTORS AND TECHNICIANS

Customer and Team Management

Centralized database

For distributors and technicians, Airvice allows grouping all compressors and customers in a single digital system, facilitating the tracking of each unit.

Complete history

View records of installations, maintenance visits and parts replacements to make data-driven decisions. Plus reports of all work performed.

Get superior performance,

Obtén la serie AIRBOX® CERO

free quote

Downloads

compressed air study